Rheology techniques used at the Zeta Rheology Centre

The majority of our measurements are made using a TA Instruments AR-G2 controlled stress rheometer, together with a range of geometries: plate-plate, cone-plate, double gap concentric cylinder or vane geometry.

Viscosity and flow

Typically our viscosity or flow measurement data is collected as viscosity vs shear rate or shear stress vs shear rate using rotational viscometry with cone and plate, parallel plate or double gap geometries. Fluids exhibiting Newtonian behaviour have a constant viscosity over a range of shear rate, while fluids with non-Newtonian behaviour have a viscosity which changes with the applied shear rate.

Temperature ramps

Rheological data can be obtained between 5 to 100ºC, and is routinely measured between 5 to 80ºC. Sweeps between these ranges can also be conducted to investigate a material’s behaviour or stability with respect to changing temperature. Temperature ramps are important for lubricants and food products.

Rheology Modelling and Data Fitting for Process Design and Pump-sizing.

Rheological models can be fitted to flow curve data in order to acquire parameters for engineering and process design calculations. These models include:

- Bingham

- Casson

- Power Law

- Herschel Bulkley

- Sisko

- Williamson

- Cross

- Ellis

- Carreau

- Arrhenius

Yield point/stress measurement

We measure the yield point of a slurry using plate-plate, concentric cylinder, or rotating vane geometry. The yield stress corresponds to the stress required to begin a significant movement in the sample. This movement disturbs a sample’s structure, resulting in a sharp viscosity decrease. At this point, the sample transforms from a solid-like state to a flowing liquid.

Zero-shear viscosity

To measure the zero-shear viscosity an increasing stress is applied at constant frequency to a sample. This determines the sample’s viscoelastic characteristics, and in particular yields the linear viscoelastic region of the sample. This testing can be employed for greases and gels, and the zero-shear viscosity is also an important factor in emulsion/suspension stability.

Creep

Creep tests determine the viscous and elastic loss and recovery when strain is removed. This is achieved via the use of constant strain to a sample followed by its release, then measuring the sample’s recovery behaviour.

Tack testing

This kind of test determines the tack or “stickiness” of a sample via the detachment of the substance on parallel surfaces. This is often employed for foods, cosmetics, greases, adhesives and paints.

Stress relaxation

Stress relaxation can be measured by the change in force over time for a given deformation of the sample.

Other Techniques at the Zeta Rheology Centre

Particle Size Analysis by Acoustic Attenuation

We use Acoustic Attenuation Spectroscopy which is particularly well suited for particle sizing of high concentration muds, colloids, suspensions and emulsions.

Light based particle sizing techniques are inadequate for samples of high solid concentration. This is especially the case in situations where dilution of the sample would cause instability. Our instrumentation utilises multi-frequency acoustic wave attenuation to allow for the determination of particle size in such samples.

Zeta Potential

Zeta potential is the potential at the slipping plane of a solid or liquid in a colloidal dispersion. This potential is the effective surface particle charge for a particle immersed in a liquid.

The zeta potential, usually expressed in mV, is highly influenced by the pH of the solution and can be either negative or positive. The absolute magnitude of this value yields an insight into the stability and behaviour of the colloid in question.

We measure the zeta potential of a sample by determining the colloid vibration current of the colloidal dispersion.

Zeta potential can be used to forecast the long-term stability of a colloid. Particles with zeta potentials greater than ±60 mV can exhibit exceptional stability, whereas particles with zeta potentials below ±10 mV, will typically undergo aggregation unless stabilised by other means.

This measurement technique is important in the food and beverage area, where strict conformity to standards are required. Food stuffs must have consistent texture and flavour between batches. Shelf lives may be extended by formulation to stabilise any essential colloids present.

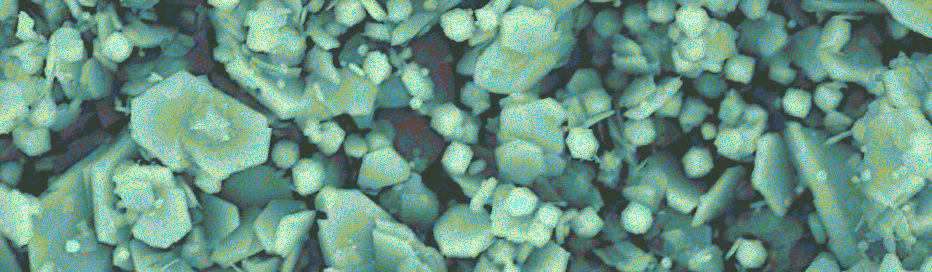

Scanning Electron Microscopy (SEM)

Particle size and charge are important but particle shape is often best examined using microscopy. Suspensions of plates, needles and blocky particles can each exhibit characteristic rheological behaviours. For example, slurries containing plate-like particles typically have a higher yield stress and a greater storage modulus. Dispersions of plate-like particles can show rheological behaviour arising from time-dependent orientation with applied stress.

Share this post